Overview of the Manufacturing Sector and Digital Transformation

The manufacturing sector stands at a critical juncture, grappling with an alarming statistic: over 80% of firms have reported a surge in cybersecurity incidents in recent years, exposing the vulnerability of an industry that drives global economic stability. This competitive landscape, where downtime can cost millions, underscores the urgent need for robust security as companies embrace digital transformation. Amid this backdrop, PGP Glass, a Mumbai-based leader in glass packaging with operations spanning multiple continents, emerges as a pivotal player navigating these turbulent waters with a daily production of 1,730 tons of glass bottles.

Globally, manufacturing contributes significantly to economic output, yet its integration of cutting-edge technologies has opened new risk frontiers. The shift toward Industry 4.0, characterized by the adoption of IoT, AI, and automation, promises unprecedented efficiency but also heightens exposure to cyber threats. For companies like PGP Glass, serving premium brands across diverse markets, securing operational technology (OT) and IoT systems is not just a technical requirement but a business imperative to maintain trust and continuity.

This transformation is reshaping how manufacturers operate, moving from isolated, manual processes to interconnected, data-driven ecosystems. The convergence of IT and OT systems is no longer optional but a necessity to meet consumer demands for innovation and sustainability. As PGP Glass exemplifies, this journey involves not only adopting advanced tools but also fortifying defenses against an evolving threat landscape that targets the very backbone of industrial operations.

Industry Trends and Market Dynamics in OT and IoT Adoption

Emerging Technologies and Key Drivers

The manufacturing sector is witnessing a technological renaissance, with Industry 4.0 propelling the adoption of IoT, AI, and machine learning to optimize production and supply chains. PGP Glass provides a compelling case study, having transitioned from paper-based systems to fully digital processes over recent years, integrating over 12,000 sensors for energy monitoring alone. Such advancements enable real-time data analysis, driving operational efficiency gains of 0.5% to 1% annually, a critical edge in a razor-thin margin industry.

Beyond efficiency, sustainability acts as a powerful motivator for IT/OT convergence, with digital tools helping firms like PGP Glass achieve energy reductions of 1% to 2%, translating to substantial cost savings. Consumer expectations for innovative, eco-friendly solutions further accelerate this shift, pushing manufacturers to leverage connected devices for smarter decision-making. These drivers collectively reshape the sector, compelling companies to balance technological progress with the inherent risks of expanded digital footprints.

The convergence of IT and OT systems, while transformative, demands a rethinking of traditional workflows. Manufacturers are increasingly adopting cloud-based IoT platforms, as seen with PGP Glass’s use of Azure and AWS, to centralize data from manufacturing and energy systems. This integration not only enhances agility but also underscores the need for robust security frameworks to protect against vulnerabilities introduced by interconnected environments.

Market Data and Growth Projections

Data paints a stark picture of the cybersecurity challenges facing manufacturing, with 80% of firms noting increased threats and an 87% rise in ransomware attacks targeting industrial entities. The financial toll is staggering, with the average breach costing $6 million, a figure that reflects both direct losses and prolonged operational disruptions. These statistics highlight the urgency of securing OT and IoT as digital adoption scales across the sector.

Looking ahead, research from Omdia indicates that 70% of manufacturing firms are expected to achieve IT/OT convergence within the current year, signaling a rapid move toward integrated systems. However, only a small fraction—19%—have reached advanced security maturity, leaving many exposed to escalating risks. The financial impact of breaches, coupled with downtime (75% of incidents cause partial shutdowns), emphasizes the critical need for investment in protective measures.

Projections suggest that secure digital adoption will fuel future growth, with firms prioritizing cybersecurity likely to gain a competitive advantage. The market for OT-specific security solutions is expanding, driven by the recognition that traditional IT defenses fall short in industrial contexts. As manufacturers navigate this trajectory, the focus on resilience and proactive risk management will shape the sector’s ability to sustain innovation without succumbing to cyber threats.

Challenges in Securing OT and IoT During Digital Transformation

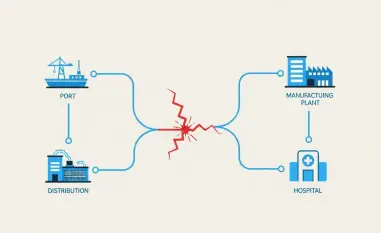

The convergence of IT and OT systems has significantly widened the attack surface for manufacturers, creating entry points for cyber adversaries. Historically, OT components like SCADA and PLCs were designed for functionality, not security, lacking the built-in protections common in IT environments. For PGP Glass, initial gaps in OT monitoring posed substantial risks, mirroring a sector-wide struggle to safeguard legacy systems against modern threats.

Detection and response times exacerbate these vulnerabilities, with the average breach in manufacturing taking 199 days to identify and 73 days to contain. Such delays often result in severe operational downtime, with 75% of incidents leading to partial shutdowns and 25% causing complete halts. These interruptions disrupt production cycles and erode customer confidence, amplifying the stakes for companies dependent on continuous operations.

Addressing these challenges requires tailored solutions, as standard IT security tools are ill-suited for OT environments. Specialized platforms and frameworks are emerging to bridge this gap, offering visibility into industrial systems without compromising performance. For manufacturers like PGP Glass, investing in such tools, alongside comprehensive training and monitoring strategies, becomes essential to mitigate risks and ensure seamless digital integration.

Regulatory and Compliance Landscape for OT and IoT Security

Navigating the regulatory environment is a cornerstone of securing OT and IoT in manufacturing, with standards shaping how firms manage risks in converged systems. PGP Glass has aligned with ISO 27001 for information security management, ensuring a structured approach to safeguarding data and operations. Additionally, compliance with Europe’s Ecolabel cybersecurity requirements reflects the company’s commitment to meeting stringent global benchmarks.

These regulations are not mere formalities but critical mechanisms to reduce vulnerabilities across IT/OT environments. The push for compliance drives manufacturers to adopt best practices, from risk assessments to incident response protocols, fostering a culture of accountability. For global players serving high-profile clients, adherence to such standards builds trust, positioning them as reliable partners in a risk-averse market.

The broader regulatory landscape continues to evolve, with increasing emphasis on protecting industrial systems from cyber threats. Standards serve as a unifying force, enabling companies to align operations with international expectations while mitigating legal and financial repercussions of non-compliance. This framework not only enhances security but also strengthens industry credibility, a vital asset in a sector under constant scrutiny.

Future Outlook for OT and IoT Security in Manufacturing

As manufacturing progresses deeper into digital transformation, emerging security technologies promise to redefine traditional approaches to safeguarding OT and IoT systems. Agentless monitoring platforms, such as Armis Centrix, offer a glimpse into this future, providing comprehensive visibility into industrial devices without the overhead of traditional agents. PGP Glass’s adoption of such tools across its global facilities sets a benchmark for scalable, non-intrusive security solutions.

Market disruptors, including evolving cyber threats and economic fluctuations, will continue to challenge the sector’s security posture. With only 19% of firms currently at advanced maturity levels, there is significant room for growth in adopting robust frameworks. PGP Glass’s phased rollout, covering multiple regions with a target completion within the next six to nine months, exemplifies a strategic approach to addressing these dynamic risks.

Innovation, coupled with regulatory advancements, will shape the trajectory of OT and IoT security in manufacturing. Economic factors, such as the rising cost of breaches, will further incentivize investments in protective measures. As companies strive for resilience, the interplay of technology and policy will determine how effectively the industry can balance digital progress with the imperative of safeguarding critical operations.

Conclusion and Strategic Recommendations

Reflecting on the journey of PGP Glass, the path from manual processes to a fortified digital framework revealed both formidable challenges and remarkable achievements in securing OT and IoT systems. The company’s efforts culminated in significant benefits, including a 40-45% reduction in cybersecurity insurance premiums and enhanced protection of its reputation among premium global clients. This transformation underscored the tangible value of prioritizing security in a sector vulnerable to operational disruptions.

Moving forward, manufacturers must commit to increased investment in OT-specific security tools tailored to industrial environments, ensuring comprehensive coverage of converged systems. Adherence to global standards like ISO 27001 should be non-negotiable, providing a foundation for consistent risk management across diverse markets. Additionally, prioritizing resilience through proactive monitoring and rapid response capabilities will be crucial to maintaining operational integrity.

The broader manufacturing sector stands to gain from embracing a strategic mindset that views security not as a cost but as a competitive differentiator. By fostering collaboration between technology providers and regulatory bodies, companies can stay ahead of emerging threats while driving innovation. Ultimately, safeguarding both operations and brand trust will define success in an era where digital transformation and cybersecurity are inextricably linked.