With a deep background in securing multinational corporations against digital and physical threats, Malik Haidar has a unique vantage point on how analytics and intelligence can reshape industries. He specializes in integrating robust security frameworks with core business objectives, making his insights particularly relevant as industries like construction begin to adopt sophisticated AI and IoT solutions. Our discussion centers on the shift from cloud-dependent systems to on-site, edge-based intelligence, exploring how this technology not only enhances worker safety but also drives operational efficiency by providing real-time, actionable data where it’s needed most—on the ground.

Cloud-based video analytics often face challenges like poor connectivity and response delays. How does an edge-based system overcome these specific hurdles, and what does the step-by-step process look like from the moment a hazard is detected to an alert being triggered on-site?

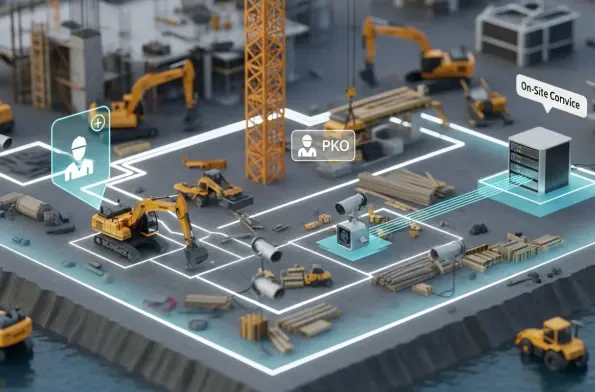

That’s really the core of the problem these edge systems are designed to solve. A construction site is a chaotic, dynamic environment, often with terrible or fluctuating connectivity. When you rely on the cloud, you’re sending massive video streams off-site, waiting for them to be processed, and then waiting for an alert to be sent back. That round trip introduces a critical delay, and in a safety scenario, a few seconds can be the difference between a near-miss and a serious accident. An edge-based system, like the EC5000, completely short-circuits that delay. The intelligence is right there on-site. The process becomes immediate: a camera captures a worker entering a restricted zone, the footage is analyzed in real-time by the local AI computer, and a notification is instantly triggered on the foreman’s mobile device. There’s no dependency on an external network, which means the response is practically instantaneous and far more resilient.

The system can detect specific issues like PPE non-compliance and restricted-zone breaches. Could you walk us through how the AI is trained to identify these risks and what immediate, automated actions are triggered on the ground once a violation is detected? Please provide an example.

The training process for the AI is quite intensive. It involves feeding the model thousands of images and video clips from construction sites to teach it what’s normal and what’s an anomaly. For PPE, it learns to recognize the shape and color of a hard hat, the presence of a high-visibility vest, and so on. It’s trained on countless examples of workers with and without the proper gear in different lighting conditions and from various camera angles. Once deployed, it constantly scans the live video feeds for these patterns. So, imagine a scenario where a worker, maybe in a rush, steps out of a vehicle without putting on their hard hat. The on-site AI immediately detects the absence of the required PPE. The system doesn’t just sit on that information; it can be configured to trigger an automated, local audio alert in that zone while simultaneously pushing a notification with a video snapshot to the site safety manager’s dashboard. It’s an immediate, closed-loop intervention.

Beyond identifying a hazard, the system initiates actions and stores evidence. How is this data used for both immediate intervention via mobile alerts and for long-term safety training programs?

This is where the technology moves from being just a warning system to a tool for cultural change. In the short term, the mobile alerts are about immediate intervention—getting a supervisor to the scene to correct a dangerous behavior before an incident occurs. But every one of those events, whether it’s a PPE violation or a zone breach, is automatically logged with video evidence. This creates an incredibly valuable repository of data. Instead of relying on vague incident reports, safety managers can use these concrete examples in their weekly training sessions. They can show teams the exact situations where risks are being taken, making the training far more impactful than a generic presentation. Over time, you can analyze this data to spot trends—like if a particular zone has frequent breaches—and address the root cause, whether it’s inadequate signage or a flawed workflow.

Implementing new technology like on-site AI involves changing established workflows. What are the key steps for a construction firm to deploy this system, and what are the biggest challenges they face in integrating it with their existing safety protocols and management dashboards?

The first step is always a pilot program on a specific site to identify the most critical risks to monitor. You don’t try to boil the ocean. The biggest challenge isn’t the technology itself—the hardware is designed for flexible deployment. The real hurdle is human and procedural. You have to integrate the alerts into the existing chain of command. Who gets the notification? What is their required response? You need to clearly define these new mobile workflows. Another challenge is dashboard integration. Most large firms already have a central management dashboard for project tracking. The key is to feed the AI-generated safety alerts into that same dashboard, so safety metrics are viewed alongside project progress, not in a separate silo. This ensures that safety becomes a visible, data-driven part of daily operations, not just a compliance checklist.

This technology promises to improve not just safety but also operational efficiency. Can you share an anecdote or a scenario where faster, localized analytics prevented a costly operational delay, in addition to preventing a potential accident on a construction site?

Absolutely. Think about a designated laydown yard where heavy materials are delivered. If an unauthorized vehicle or person enters that zone while a crane is operating, protocol demands a complete stop-work order until the area is cleared. With a cloud-based system, it might take several minutes for a remote monitor to spot the breach and radio the site. By then, the crane operator has already halted the lift, and you have a crew of five people standing around waiting, which kills productivity. With an on-site AI, the breach is detected instantly. An alert goes directly to the crane operator and the ground crew, allowing them to pause for thirty seconds while the person is escorted out, rather than shutting down the entire operation for ten minutes. It’s a small difference in time, but when you multiply that across a year-long project, the cost savings from avoided delays are substantial, all while making the operation fundamentally safer.

What is your forecast for the future of AI and edge computing in the construction industry?

I believe we’re at the very beginning of a major transformation. Right now, we’re focused on specific use cases like PPE and zone detection, but the potential is far broader. In the near future, these edge AI systems will be integrated with other IoT sensors to create a comprehensive, real-time digital twin of the entire construction site. The AI won’t just see a person without a helmet; it will know that person is walking toward an active piece of heavy machinery that is moving in their direction. It will be able to predict collisions, identify structural stresses from video analysis, and even monitor environmental conditions. Edge computing will become the central nervous system for the job site, making proactive, predictive safety the standard, not the exception, and fundamentally reshaping how we manage risk and efficiency in one of our most vital industries.